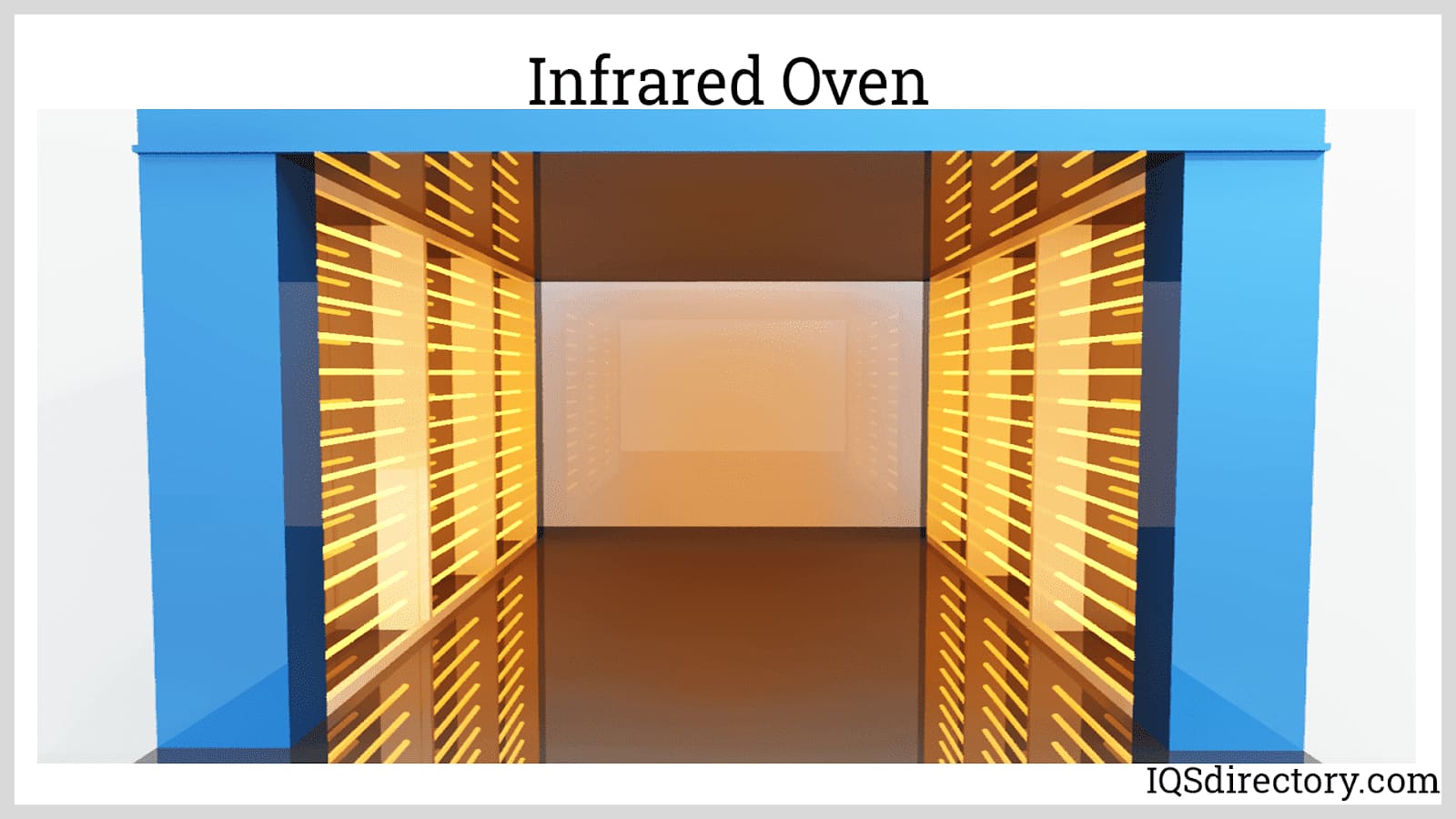

Infrared ovens are multipurpose appliances that can cook food by the heat generated by energy waves. Infrared ovens are faster than conventional cooking methods and more efficient because they can do more than just cook food. Read More…

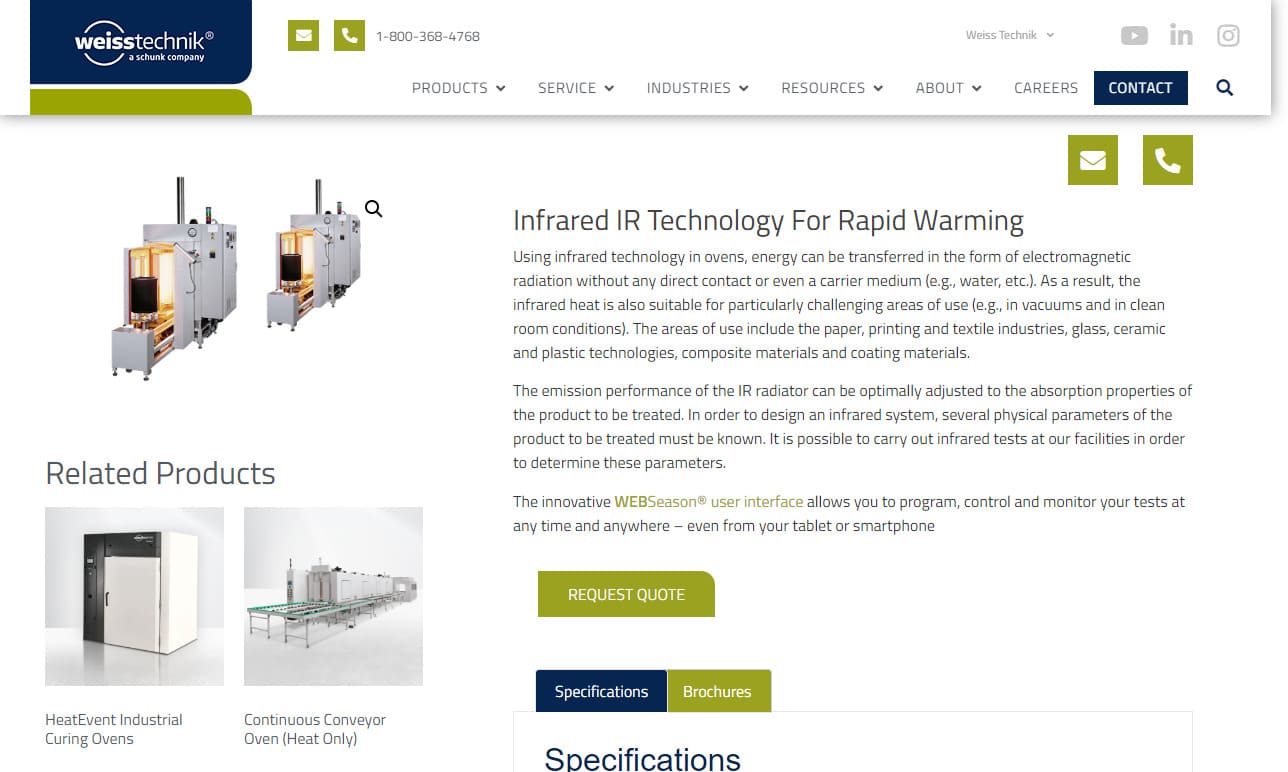

Weiss Envirotronics is a worldwide leader in the design, manufacturer and service of environmental test chambers. A complete line of standard and custom chambers, from bench top models to full walk-in and drive-in solutions to meet any testing requirement. Not sure what you need? Let one of our applications engineers help. Weiss Envirotronics, Inc is ISO 9001 registered and A2LA accredited.

Complete finishing systems are designed around your specific process needs and are optimized to fit within your space requirements. We specialize in producing paint systems for wet and powder coatings, while also providing comprehensive design, fabrication, installation, start-up, and training services. Our complete finishing systems consist of an overhead conveyor, pretreatment washer, dry-off...

Surface Combustion offers a diverse product offering for batch, continuous furnace designs for atmosphere, non-atmosphere, or vacuum processing of ferrous and/or nonferrous components/materials. The convection design is optimal for temperatures between 350°F – 1400°F and are engineered to perform and built to last.

Belco Industries is a leading supplier of high-quality finishing systems, including industrial ovens: batch ovens, moisture drying ovens, infrared preheat, dewatering, E-coat cure ovens, powder coat cure ovens, paint bake ovens and more. We attribute our success to our diversified product line and our ability to change with the demands of the modern industrial market. Call today for more...

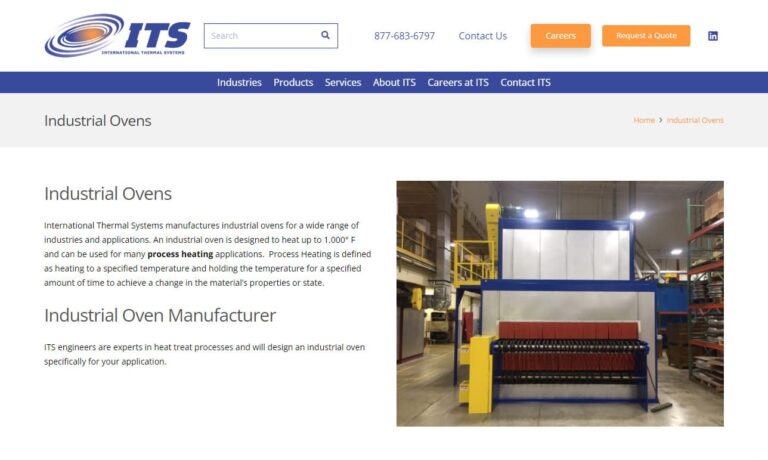

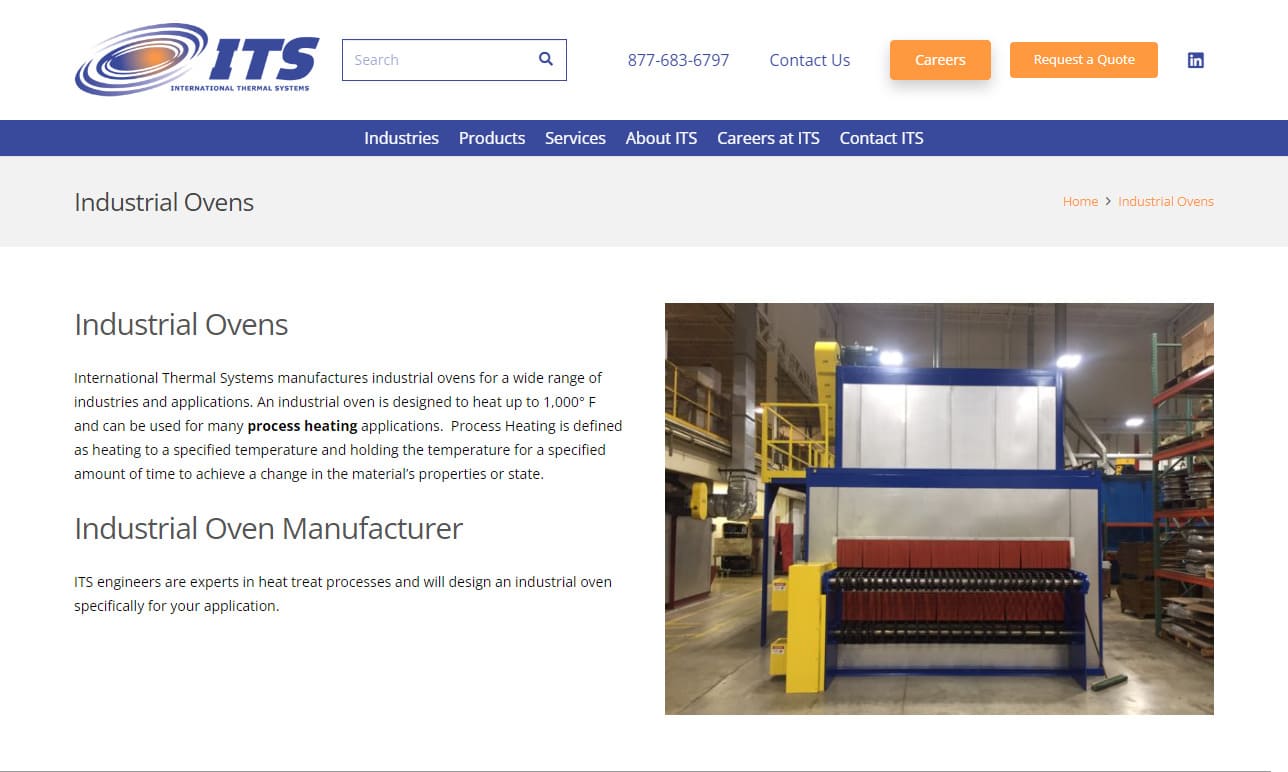

International Thermal Systems manufactures industrial ovens for a wide range of industries and applications. An industrial oven is designed to heat up to 1,000° F and can be used for many process heating applications. Process Heating is defined as heating to a specified temperature and holding the temperature for a specified amount of time to achieve a change in the material’s properties or...

At Ajax Tocco Magnethermic Corp., we are dedicated to pioneering excellence in the field of industrial heating solutions. Our company stands at the forefront of advanced thermal technology, specializing in the design and manufacture of high-performance induction heating systems, industrial ovens, and associated equipment. Our extensive portfolio reflects our commitment to innovation and quality,...

More Infrared Oven Manufacturers

What are Infrared Ovens?

Infrared ovens are multipurpose appliances that can cook food by the heat generated by energy waves. Infrared ovens are faster than conventional cooking methods and more efficient because they can do more than just cook food.

These ovens must be handled with care because they can reach extreme temperatures.

How Infrared Ovens Work

Infrared ovens work by converting electrical energy into radiant heat. When an object is cooked by an infrared oven, the shields and reflectors inside the appliance heat the object.

The object being cooked absorbs the energy produced by the infrared oven; for instance, when a roast is being prepared using an infrared oven, the moisture inside the roast absorbs the energy generated by the infrared.

The molecules in the roast vibrate at high speed, causing friction that creates the heat to cook the roast. When cooking food with an infrared oven, a person must not spend a long time in front of infrared emitters of high intensity. This is a precaution that must be taken when using infrared ovens.

Types of Infrared Ovens

The different types of infrared ovens include:

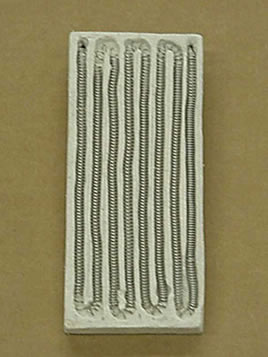

Electric Infrared Ovens

These types of ovens make use of electric infrared heaters for the radiation of heat into a part. They are found in different shapes and can be used for laminating, annealing, curing adhesives, thermoforming, curing powder coatings, and sintering.

Electric infrared ovens are considered the fastest way of heating a part. These ovens consist of elements that can be shaped to match the profile of the workpiece. This will maximize the amount of energy available to be absorbed into the part.

Gas Catalytic Infrared Pre Gel Ovens

These types of ovens sit just in front of a convection oven. They allow the newly applied powder to gel and initiate the process of powder flow as it begins a chemical change under heat. However, they are not designed to entirely cure the powder, as this procedure is completed in the conventional oven.

Infrared Convection Combination Ovens

These ovens combine industrial furnace systems and industrial ovens to produce a combination of radiant/convective heating. They achieve this by combining infrared heating elements with recirculation blowers that are plug-style plenum.

These combination systems provide controllable, efficient, and fast electric infrared heating. They also offer uniform heating that is impingement assisted, and they also provide convection drying.

Infrared Curing Oven

These types of ovens transfer heat rapidly with radiation directly to the coating. Infrared cure ovens cure a coating much faster than convection ovens because infrared cure ovens can directly heat the part that is being coated.

They also don't waste BTUs to heat the entire substrate or the surrounding environment.

Infrared Composite Furnace

These types of furnaces are used for preheating and forming carbon composites to make parts used in aerospace. They do this by preheating carbon composite material blanks before press forming.

Each furnace chamber consists of medium wave quartz tube heaters for heating the composite blank from below and above. The furnace consists of an internal stainless steel structure that supports the composite blank between lower and upper heating elements during the heat cycle.

Applications and Benefits of Infrared Ovens

The applications and benefits of infrared ovens include:

Applications of Infrared Ovens

- Baking

- Curing

- Bonding

- Burning off

- Preheating

- Thermoforming

- Cooking

- Fusion

- Shrinking

- Laminating

- Drying a wide range of materials

Benefits of Infrared Ovens

- Fast response -The infrared element provides outstanding control of the process temperature and heat output due to its low thermal mass.

- High heating rates - The electric infrared heating element has a high source temperature. This will lead to fast heating because of high thermal transfer.

- Controllable output - The output of electric infrared oven systems can be precisely controlled to match the process's temperature requirements.

- Uniform heating - Better temperature uniformity is achieved by the convection heating component.

- Clean heating - The electric heat source used by infrared heaters is environmentally clean and efficient.

- High heating efficiencies - Input electrical power is converted to radiant heat energy, up to 88%.

- Less noise production - Infrared ovens produce less noise due to low air movement.

- Small size - Infrared ovens occupy less space due to their smaller size, which results from the fewer parts used to build them.

- Less maintenance required - Due to the smaller number of parts required for building infrared ovens, they need less maintenance.

Choosing the Correct Infrared Ovens Supplier

To make sure you have the most constructive outcome when purchasing Infrared Ovens from a(n) Infrared Ovens Manufacturer, it is important to compare at least 5 Companies using our list of Infrared Ovens suppliers. Each Infrared Ovens Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Infrared Ovens company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Infrared Ovens businesses with the same form.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches