Industrial ovens are thermal processing machines that provide various applications with the very important process of heat treatment. During this process, heat speeds up the molecular activity inside an object. Inside solid objects, molecules are arranged in lattices that vibrate from the heat, while in gases, these molecules collide. This activity changes the properties of the object it is heating, and strengthens it. Read More…

Weiss Envirotronics is a worldwide leader in the design, manufacturer and service of environmental test chambers. A complete line of standard and custom chambers, from bench top models to full walk-in and drive-in solutions to meet any testing requirement. Not sure what you need? Let one of our applications engineers help. Weiss Envirotronics, Inc is ISO 9001 registered and A2LA accredited.

Complete finishing systems are designed around your specific process needs and are optimized to fit within your space requirements. We specialize in producing paint systems for wet and powder coatings, while also providing comprehensive design, fabrication, installation, start-up, and training services. Our complete finishing systems consist of an overhead conveyor, pretreatment washer, dry-off...

Surface Combustion offers a diverse product offering for batch, continuous furnace designs for atmosphere, non-atmosphere, or vacuum processing of ferrous and/or nonferrous components/materials. The convection design is optimal for temperatures between 350°F – 1400°F and are engineered to perform and built to last.

Since 1961, Thermal Engineering’s process & finishing systems contribute to the product quality of many automobile, furniture, paper, plastic & building products. Thermal’s industrial ovens offer savings in regards to time, energy & space and its solutions are designed for maximum flexibility for customers' use and with all applicable safety & code requirements that encompass a quality system.

Kleenair Products designs, engineers and manufactures high quality industrial ovens for industrial process systems. Our aging ovens, coloring ovens, drying ovens and food baking ovens serve many industries. We test fire each oven before shipping, guaranteeing your satisfaction. You will also find other process systems at Kleenair, including furnaces, drying systems, and energy recovery equipment.

C.A. Litzler Co. is ready to help you with your heat processing needs. With 60 years of designing and manufacturing experience, you can rest assured that the industrial oven you need can be built by us. We are determined to find the product that will meet your every need and requirement. Visit our website or give us a call today to learn more about how we can meet your needs.

More Industrial Oven Manufacturers

Please note: Industrial ovens serve distinct purposes from furnaces. Furnaces can achieve much higher temperatures (exceeding 2000℉) and are typically larger in size. It’s common for industrial manufacturers to also specialize in furnace production, offering both industrial ovens and industrial furnaces as part of their product lines to meet a wide range of heat processing needs.

Industrial Oven Applications Across Industries

Industrial ovens are vital thermal processing equipment used across a broad spectrum of industries, delivering precise heat treatment for an array of production and research purposes. Common industries utilizing industrial ovens include:

- Manufacturing (metal, plastics, composites, ceramics, glass)

- Electronics assembly and PCB manufacturing

- Food and beverage production (baking, drying, roasting, pasteurization)

- Healthcare, medical device sterilization, and pharmaceuticals

- Chemical processing, coatings, and adhesives

- Research & development and materials testing (laboratory ovens)

- Aerospace and defense (composite curing, stress relieving)

- Automotive industry (parts drying, powder coating, curing)

- Metal forming and heat treating (annealing, tempering, sintering)

- Textiles and carpet manufacturing

- Energy and fuel cell development

Industrial ovens play a pivotal role in enhancing the strength of metal products, ensuring hygienic conditions in healthcare facilities, and expanding the versatility of extruded polymer goods. They are indispensable in treating a wide array of products such as steel coils, automotive components, tubing, electronics, construction materials, fuel cells, carpets, and textiles. Moreover, laboratories utilize these ovens to deepen their understanding and improve industrial heat transfer processes (known as laboratory ovens). This research drives advancements in reducing inefficiencies in heat transfer and pioneering new applications for heat treatment.

These processes are fundamental to modern manufacturing and industrial processing, serving specific functions such as sintering, curing, and powder coating. Sintering involves heating fine particles to fuse them into larger ones without melting, a key process in powder metallurgy and ceramics. Curing solidifies materials by subjecting them to consistent heat and dry conditions, essential for industrial coatings and polymers. During powder coating, a product is placed in an oven for two to ten minutes, where the powder melts and forms a smooth coating, aided by convection or infrared heat. Ultraviolet light then briefly cures and hardens the finish while the product remains in the oven.

History of Industrial Ovens: From Ancient Hearths to Modern Heat Processing

Since as early as 2900 BC in Central Europe, ovens have played a crucial role. Initially, they were simple pits used for boiling and roasting mammoths within nomadic yurts. These primitive ovens soon evolved, with people employing hot coals buried under ashes for more efficient cooking. Within just three centuries, hearths became widespread across settlements, serving dual purposes of cooking and brick-making.

The hearth-style brick ovens eventually transformed into kilns, a concept introduced by the Greeks, which were utilized not only for baking bread but also for pottery. As time progressed, ceramic and earth ovens were phased out in favor of fireplaces and cauldrons, marking a significant shift in culinary technology. Over subsequent centuries, ovens adapted to various energy sources, from coal and wood to iron gas, and eventually, electricity.

During the Industrial Revolution, industrial ovens saw a transformative breakthrough. In the 1700s, Philo Penfield Stewart introduced the Stewart Oberlin iron oven, marking a shift towards smaller, more ventilated designs. By the early 1800s, coal ovens were being manufactured, followed by James Sharp’s pioneering gas oven patent in 1826. Gustaf Dalen further innovated in 1922 with the AGA cooker, and Percy Spencer revolutionized kitchens in 1946 with the compact yet groundbreaking microwave oven. Today, high-tech ovens, including microwaves, cater to diverse applications, ranging from compact designs to large-scale models in commercial and industrial settings.

How Industrial Ovens Work: A Guide to Heat Transfer Methods

Industrial ovens harness heat and mass transfer through radiant infrared heat, conduction, convection, or a blend of these methods to achieve precise temperature control and uniform processing.

In industrial ovens, infrared radiation stands out as the most efficient method for transferring heat. This technique is especially effective for surface heating and rapid thermal processing. Conversely, natural convection ranks as the simplest among these methods. Gravity initiates fluid movement, causing heated molecules to rise and cooler ones to descend. This circulation facilitates heat transfer through gases and liquids. Typical gases employed for heat generation are natural gas and propane, making gas-fired ovens a common choice for high-throughput applications.

Conduction, less favored for large-scale industrial use, involves heat transferring initially to air within the oven, which then heats solid objects, spreading throughout them. Although alternative methods exist, they prove less efficient and are seldom utilized in demanding industrial settings.

Types of Industrial Ovens and Their Uses

When researching or selecting an industrial oven, understanding the main categories and their capabilities is essential. The primary types include:

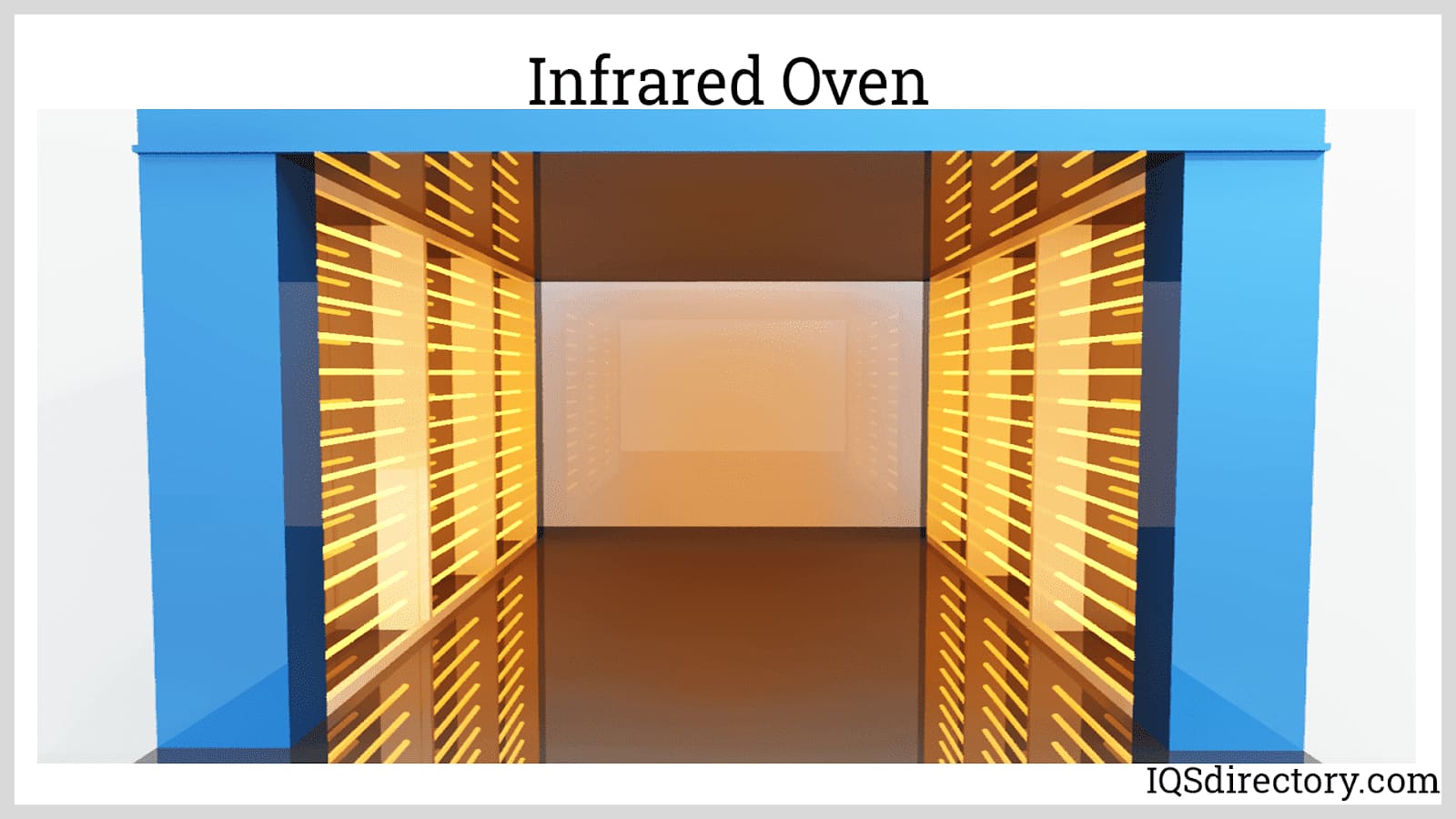

Infrared Oven

Infrared ovens utilize electromagnetic radiation for heat transfer. By bypassing the need to heat the air within the enclosure, these ovens directly apply electromagnetic waves emitted from a tungsten coil onto the product. Infrared ovens are ideal for rapid heating, energy efficiency, and processes such as drying coatings and adhesives, curing paint, and heat-treating plastics or metals where fast cycle times are required.

Convection Oven

Convection ovens employ either an electrified coil or a gas-fired heating element to ensure uniform internal heating. This method is ideal for smaller quantities; however, larger batches may experience uneven heat distribution unless the oven is equipped with a fan to enhance air circulation and overcome this challenge. Commercial convection ovens are commonly utilized in extensive baking operations, as well as in drying, sterilizing, and curing processes where consistent temperature throughout the chamber is critical.

Batch Oven

Industrial batch ovens come in diverse sizes, from compact and mobile units to expansive fixtures that occupy entire rooms permanently. These ovens specialize in processing materials in discrete batches, making them favored by large-scale commercial manufacturers handling substantial product volumes, as well as by smaller industrial heat treaters who value their precise and uniform heat distribution. Referred to interchangeably as cabinet ovens or walk-in ovens, batch ovens support various processes such as curing, drying, annealing, aging, and stress relieving of metals and composites.

Vacuum Oven

Some batch ovens are designed to release the enclosed atmosphere, preventing heat-treated metals from suffering surface oxidation. These specialized ovens are known as vacuum ovens. Vacuum ovens are essential in applications requiring controlled atmospheres, such as electronics manufacturing, pharmaceutical processing, and laboratory testing, where oxidation or contamination must be minimized.

Continuous Oven

Continuous ovens, in contrast to batch ovens, excel in multitasking. With dedicated warming and cooling stations, they accelerate thermal processes more efficiently than their counterparts. Ideal for large-scale operations demanding uniform heat treatment, such as food processing, paint curing, and automated manufacturing lines that require uninterrupted product flow and high throughput.

Conveyor Oven

Conveyor ovens, designed to shuttle products through a heated chamber via automated conveyor belts, typically find utility primarily in large-scale operations. Their cost-effectiveness hinges on a consistent flow of products to justify their operation. Conveyor ovens are widely used for food baking, solder reflow in electronics, and curing coatings on automotive or industrial parts.

In contrast, batch and continuous ovens, though distinct in operation, can each fulfill roles such as sintering, robust powder coating, drying, or curing applications. When evaluating whether a batch or continuous oven is right for your process, consider your production volume, product size, and the need for process flexibility versus automation.

Drying Oven

Drying ovens efficiently extract moisture from raw materials using a structured three-step process. First, in the heat-up phase, substances reach their optimal temperature within the oven. Next, during the soak phase, materials absorb this heat for a specified duration. Lastly, in the cool-down stage, hot air exits while cooler air replaces it. Drying ovens excel in tasks like sterilization, incubating temperature-sensitive experiments, and conducting temperature tests. They are vital for laboratories, pharmaceutical processing, and material research where precise dehydration is required.

Tunnel Oven

Tunnel ovens are cylindrical appliances designed to heat raw materials as they travel through their length. These materials can be fed into the oven either continuously or in batches using a conveyor belt. Tunnel ovens generate heat from various fuel sources, working in tandem with the belt’s speed. Ideal for cooking, these ovens are especially suited for preparing meat and baked goods. In industrial contexts, tunnel ovens are also used for curing composites and drying textiles in high-volume production lines.

Burn-off Oven

Burn-off ovens, also called heat-cleaning ovens, purify objects by incinerating contaminants and coatings. These ovens effectively remove substances such as varnish, paint, grease, epoxy, oil, and bonded rubber. They are particularly useful for cleaning and decoating automobiles, electrical motors, industrial tooling, and various machinery, providing an environmentally friendly solution for parts cleaning and maintenance.

Key Equipment Components in Industrial Ovens

Every custom oven is unique, yet most industrial ovens typically share these key components for optimal heat management, safety, and process control:

- Motor: Drives air circulation fans or conveyor systems to ensure uniform heat distribution.

- Duct Network: Facilitates ventilation and exhaust, maintaining air quality and temperature stability.

- Fans: Used for both exhaust and recirculation, essential for convection and even heat transfer.

- Purge Timers: Control pre-heating and ensure safe removal of volatile gases before ignition.

- Flame Controllers and Burners: Manage heat generation and combustion for gas-fired ovens.

- Temperature Sensors and Controls: Provide precise monitoring and regulation for process consistency.

- Safety Interlocks: Prevent operation under unsafe conditions, protecting personnel and equipment.

How to Use an Industrial Oven: Best Practices and Installation Tips

Each model of oven is unique, so we can’t provide exact instructions for yours. However, we can offer some general guidelines for industrial oven installation, operation, and maintenance to ensure optimal performance, efficiency, and safety.

- Installation Location: Choose a site that protects the oven from high ambient temperatures, mechanical damage, vibrations, and other hazards. Avoid placing your oven directly against the wall to allow for proper ventilation and thermal expansion.

- Leveling and Support: If your cabinet is made of stainless steel, which is common, you’ll need to level it with a shim. This shim helps support the oven as it expands during use (stainless steel expands when heated).

- Ventilation: Ensure that your installation site has adequate ventilation to prevent heat buildup and to exhaust fumes or gases safely.

- Compliance: Make sure you follow all relevant standards, specifications, and codes (such as NFPA 86) when installing and using your oven. This is especially important for gas-fired ovens, which require proper gas line installation and leak testing.

- Power Supply: Verify that your electrical supply matches the oven’s requirements. Improper voltage or phase can damage controls and heating elements.

- Start-Up and Operation: Review the manufacturer’s operation manual for specific instructions. Allow the oven to reach operating temperature before loading and monitor process parameters during operation.

- Maintenance: Regularly inspect and maintain components such as fans, burners, heating elements, sensors, and safety devices to ensure reliable, efficient operation and to extend the oven’s lifespan.

If you’re unsure about installing your industrial oven, don’t hesitate to contact your supplier for guidance or professional installation assistance. Many reputable industrial oven manufacturers offer commissioning, training, and ongoing technical support to help you maximize your investment.

Benefits of Industrial Ovens for Your Business

There are many reasons to love industrial ovens. These include: air flow efficiency, speed, durability, consistency, easy temperature management, and cost effectiveness. Investing in a quality industrial oven can boost your production capabilities, reduce labor costs, and increase product quality and consistency.

Air Flow Efficiency

Air flow efficiency ensures that the heat is evenly distributed throughout any device you place in the oven. Uniform air temperature guarantees consistent heating performance, which is a crucial aspect of most machine operations. This is particularly important for applications such as powder coating, curing adhesives, and drying, where even temperature is required for product integrity.

Speed

Industrial ovens swiftly produce heat waves while conserving energy, enabling manufacturers to accomplish numerous tasks in a short span of time. High-speed ovens, such as infrared and conveyor models, can dramatically increase throughput in time-sensitive manufacturing environments.

Durability and Consistency

Constructed predominantly from stainless steel, most industrial ovens boast exceptional durability, reliability, and performance. Robust construction ensures long service life and minimizes downtime due to maintenance or repairs, which is essential for high-volume and mission-critical applications.

Temperature Management

Industrial ovens offer effortless temperature control and significantly reduce the risk of uneven heat distribution. Advanced control systems allow operators to set precise temperature profiles, ramp rates, and dwell times, ensuring repeatable results for every batch or product run.

Cost Effectiveness

Though prices vary, acquiring an industrial oven is relatively affordable. Moreover, their reliability makes them outstanding investments. Energy-efficient designs, minimal maintenance requirements, and increased automation further enhance cost savings over time.

Additional Advantages

- Versatility: Industrial ovens can be customized for a wide range of materials and processes, including drying, sterilizing, baking, curing, aging, annealing, tempering, and heat-treating.

- Process Control: Modern ovens feature programmable logic controllers (PLC), HMI touchscreens, and network connectivity for process monitoring, automation, and data logging.

- Safety Features: Built-in safety interlocks, alarms, and emergency stops ensure operator protection and regulatory compliance.

- Scalability: Options range from small benchtop ovens for R&D to massive walk-in ovens for industrial-scale production.

Design and Customization: Tailoring Industrial Ovens to Your Needs

Crafting an industrial oven involves taking numerous factors into account. Initially, manufacturers assess its intended use. Is the oven for food production, requiring food-grade standards, or is it meant for processing equipment? These specific applications dictate the oven’s functionality, power source (whether gas or electric), and temperature specifications. If desired, manufacturers can tailor the oven to meet your unique requirements. Customization options include chamber size, temperature range, airflow configuration (horizontal, vertical, or combination), interior materials, shelving and racking, data acquisition systems, and integration with conveyor or automation systems.

When requesting a quote or designing a custom industrial oven, consider providing the following information:

- Intended application(s) and process requirements

- Desired temperature range and control accuracy

- Product dimensions and batch or continuous throughput

- Heating method preference (electric, gas, infrared)

- Required certifications (such as UL, CE, ISO, or NFPA 86 compliance)

- Facility constraints (available space, power, and ventilation)

- Special features (humidity control, inert atmosphere, explosion-proof construction)

Need help specifying the right oven? Ask yourself: What size and type of oven do I need for my process? Will my products require special handling, racking, or material compatibility? Are there regulatory requirements for my industry?

Safety and Compliance Standards for Industrial Oven Operation

Due to their operations involving heat, gas, and more, ensuring your industrial oven meets safety standards is crucial. In the USA, the NFPA (National Fire Protection Association) sets key benchmarks for this purpose, particularly under NFPA 86: Standard for Ovens and Furnaces. These specifications guide both manufacturers and users of industrial ovens on safe practices during construction, installation, and operation, minimizing potential hazards. Other relevant standards may include OSHA, UL, CE, and ISO, depending on your location and industry.

Here are some safety tips to ensure your well-being at all times:

- Always wear appropriate protective gear to prevent direct inhalation of gases and contact with hot surfaces or electrical components.

- Ensure that heating compartments are tightly sealed to prevent spills from spreading easily.

- Use ducts constructed from non-combustible materials.

- Conduct regular inspections of ovens in line with safety standards and manufacturer guidelines.

- Keep moving parts adequately lubricated on a routine basis.

- Never leave an oven unattended for any reason.

Proactive safety measures and scheduled maintenance are critical to avoiding unscheduled downtime, product loss, or safety incidents. For more information, consult your manufacturer or visit NFPA’s website for detailed compliance resources.

Industrial Oven Buying Guide: What to Consider When Choosing a Manufacturer

Finding the right manufacturer can be a daunting task. Begin by compiling a list of trusted sources. Right here, just a scroll away, you’ve completed the first step! We’ve done the legwork to identify top-tier industrial oven companies with extensive experience and a solid reputation. Their profiles are conveniently listed on this page.

How to Choose the Right Industrial Oven Manufacturer:

- Explore company websites and review product specifications, certifications, and customer testimonials.

- Look for companies that align with your specific requirements in terms of oven type, application, and industry expertise.

- Select three or four that pique your interest and reach out to each with your project details. Questions to ask include: What is your experience with my industry/application? Can you provide case studies or client references?

- During your discussions, ensure they provide essential services such as standard certifications, factory testing, troubleshooting, delivery, installation, operator training, and post-installation support.

- Consider lead times, warranty coverage, technical support, and availability of spare parts.

Once you’ve identified your ideal match, reach out again via phone or email to kickstart your project. A collaborative approach with your selected manufacturer ensures your oven is precisely tailored to your needs, ensuring long-term value and operational efficiency.

Still have questions about industrial ovens? Explore our FAQs below or use search prompts such as:

- What type of industrial oven is best for my application?

- How much does an industrial oven cost, and what affects pricing?

- What are the maintenance requirements for commercial ovens?

- How do I ensure compliance with safety standards?

- Which manufacturers offer custom oven solutions?

- What are the differences between batch and continuous ovens?

- Can I retrofit my existing oven for new processes?

For even more information on environmental testing and precision heating technology, check out our Environmental Test Chambers website.

What is the main difference between industrial ovens and furnaces?

Industrial ovens are designed for precise heat treatment at lower temperatures and are typically smaller, while furnaces can reach much higher temperatures (exceeding 2000℉) and tend to be larger. Many manufacturers offer both as part of their product lines to serve diverse heat processing needs.

What are common applications for industrial ovens across industries?

Industrial ovens are used in manufacturing, electronics, food processing, healthcare sterilization, chemical processing, laboratory research, aerospace, automotive, metal heat treating, textiles, and energy sectors. Applications include drying, curing, baking, annealing, sterilizing, powder coating, and more.

How do industrial ovens transfer heat to materials?

Industrial ovens use infrared radiation, convection, conduction, or combinations of these methods to transfer heat. Infrared is efficient for surface and rapid heating, convection ensures even heat distribution, and conduction transfers heat from the air to solid objects, though it’s less common for large-scale uses.

What are the primary types of industrial ovens and their uses?

The main types include infrared ovens (for rapid, efficient heating), convection ovens (for uniform heating), batch ovens (for processing batches), vacuum ovens (for oxidation-sensitive materials), continuous ovens (for automated, high-throughput lines), conveyor ovens (for automated transport), drying ovens (for dehydration), tunnel ovens (for continuous or batch heating), and burn-off ovens (for cleaning and decoating).

What are key components found in industrial ovens?

Common components include motors, duct networks, exhaust and recirculation fans, purge timers, flame controllers and burners (for gas-fired ovens), temperature sensors and controls, and safety interlocks. These ensure efficient heat management, safety, and optimal process control.

What installation and safety tips should I follow for industrial ovens?

Install ovens away from hazards with proper ventilation, level and shim stainless steel cabinets, ensure electrical compliance, follow standards like NFPA 86, and maintain regular inspections. Always wear protective gear, never leave ovens unattended, and conduct routine maintenance to ensure safety and reliability.

How can industrial ovens be customized for specific needs?

Industrial ovens can be tailored by size, temperature range, airflow configuration, materials, racking, control systems, and integration with automation or conveyors. Providing your intended application, temperature needs, product size, and required certifications enables manufacturers to design a solution that matches your process requirements.

What benefits do industrial ovens offer to businesses?

Key benefits include air flow efficiency, speed, durability, ease of temperature management, cost effectiveness, versatility for different processes, advanced process control, modern safety features, and scalability for any production volume.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches