A conveyor oven is an oven with a continuous flow. This oven is open on opposing sides and contains a conveying system that runs from one end of the oven to the other. A conveyor oven is designed like a batch oven, but it has the added benefit of keeping products in motion while providing continuous and uniform heat. Read More…

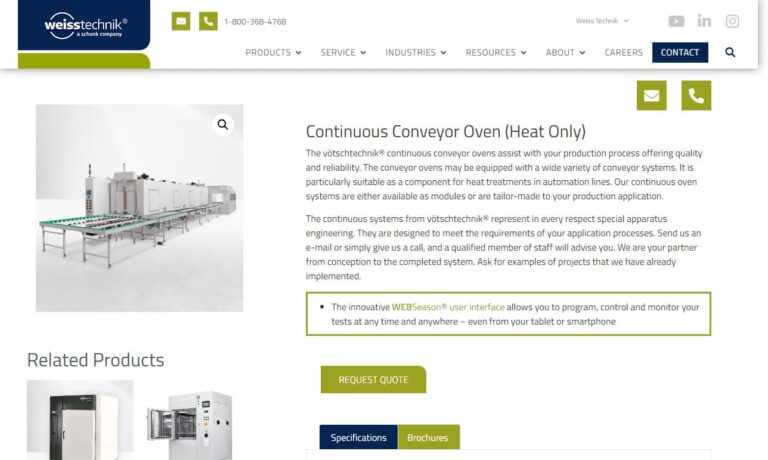

Weiss Envirotronics is a worldwide leader in the design, manufacturer and service of environmental test chambers. A complete line of standard and custom chambers, from bench top models to full walk-in and drive-in solutions to meet any testing requirement. Not sure what you need? Let one of our applications engineers help. Weiss Envirotronics, Inc is ISO 9001 registered and A2LA accredited.

Complete finishing systems are designed around your specific process needs and are optimized to fit within your space requirements. We specialize in producing paint systems for wet and powder coatings, while also providing comprehensive design, fabrication, installation, start-up, and training services. Our complete finishing systems consist of an overhead conveyor, pretreatment washer, dry-off...

Surface Combustion offers a diverse product offering for batch, continuous furnace designs for atmosphere, non-atmosphere, or vacuum processing of ferrous and/or nonferrous components/materials. The convection design is optimal for temperatures between 350°F – 1400°F and are engineered to perform and built to last.

Since 1961, Thermal Engineering’s process & finishing systems contribute to the product quality of many automobile, furniture, paper, plastic & building products. Thermal’s industrial ovens offer savings in regards to time, energy & space and its solutions are designed for maximum flexibility for customers' use and with all applicable safety & code requirements that encompass a quality system.

Kleenair Products designs, engineers and manufactures high quality industrial ovens for industrial process systems. Our aging ovens, coloring ovens, drying ovens and food baking ovens serve many industries. We test fire each oven before shipping, guaranteeing your satisfaction. You will also find other process systems at Kleenair, including furnaces, drying systems, and energy recovery equipment.

C.A. Litzler Co. is ready to help you with your heat processing needs. With 60 years of designing and manufacturing experience, you can rest assured that the industrial oven you need can be built by us. We are determined to find the product that will meet your every need and requirement. Visit our website or give us a call today to learn more about how we can meet your needs.

More Conveyor Oven Manufacturers

What Is a Conveyor Oven?

The conveyor oven is ideal for mass production and massive product runs. Conveyor ovens have a wide range of conveying systems, including overhead, roller, chain on edge, belt, and chains of different sizes, types, and shapes. The products processed by the conveyor ovens can be a few pounds or several hundred pounds.

How Conveyor Ovens Function

Conveyor ovens operate by using a powered transport method such as a conveyer to expose parts or materials to heat them at a predetermined rate. This process usually requires one operator to monitor and carry out the process. The calculations in this process are made according to how much the material will be exposed to the heat.

A conveyor system is used to move the parts in and out of the oven. Continuous process ovens are made up of parts that include pumps, nozzles, insulated panels, chains, pipe fittings, flame rods, blowers, pressure switches, burners, drives, air kits, transmissions, regulators, tooling, fixtures, controllers, fuses, and conveyors.

Types of Conveyor Ovens

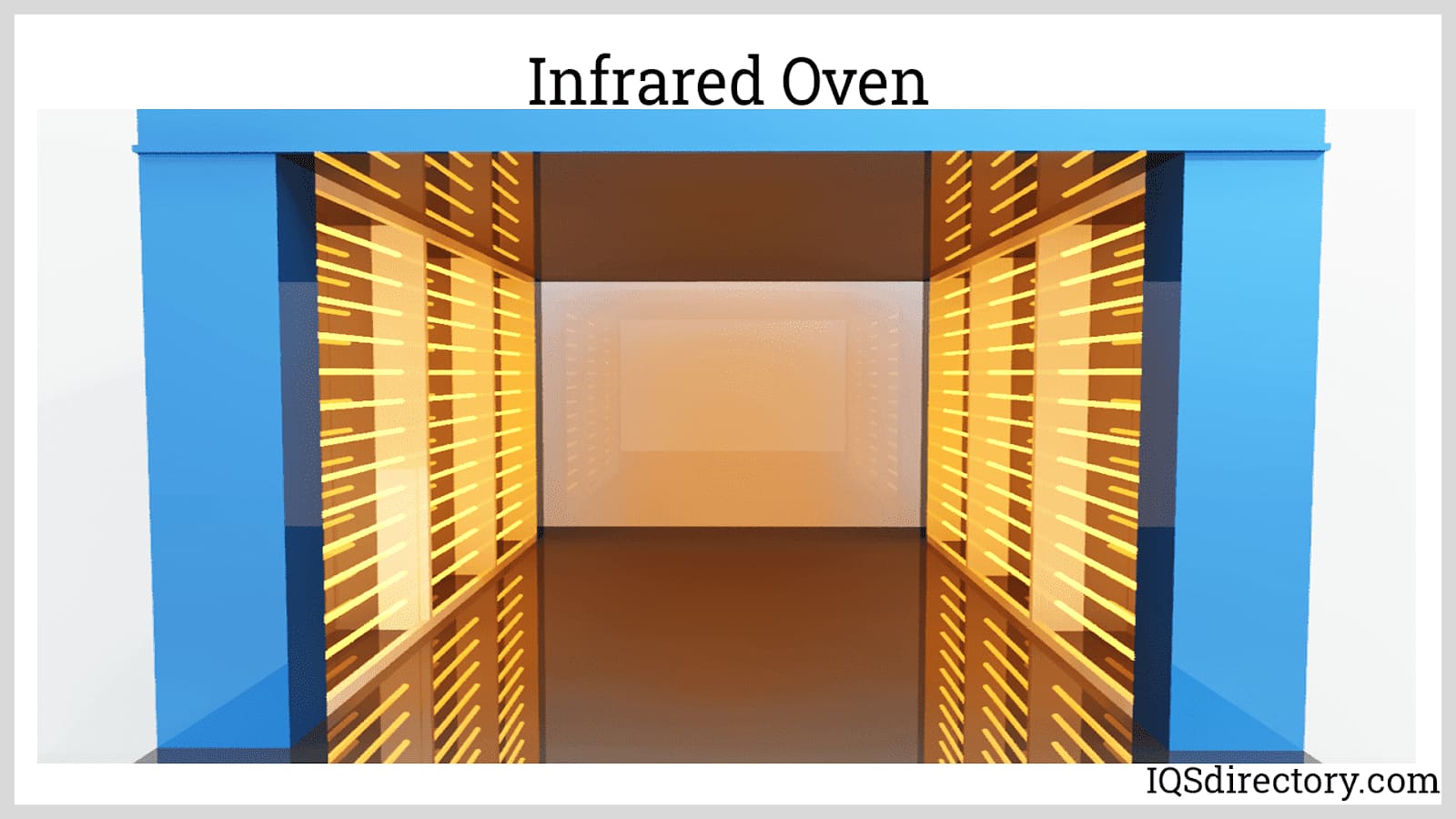

Industrial ovens consist mainly of a heated chamber, an important part of the manufacturing and finishing processes. These can provide an enclosure for heat-treating parts and components that need curing, annealing, or other methods of high-temperature treatments.

The conveyor oven is a type of industrial oven that functions by continuously, steadily, and reliably moving parts through an oven chamber to result in heat processing and treatment.

The conveyor ovens are designed in a custom manner to meet and treat a specific type of material with the use of various heating elements and conveying methods.

Vertical Conveyor Ovens

This type of conveyor oven is used with limited floor space. The parts are then conveyed using trays that are moving vertically, which can be indexed or continuously moving.

These trays are made in a fixed state on conveyor chains that move according to the paternoster pattern. Vertical conveyor ovens have exceptional temperature uniformity, reliable mechanics, easy access, and low maintenance.

Overhead Conveyor Ovens

This type uses an overhead conveying system similar to a monorail to move parts that are to be treated by multiple processes. The overhead conveyor ovens are ideal for processing high volumes of parts and components.

Overhead conveyor ovens contain a continuous circuit chain that runs on a through-track with vertical and horizontal curves, which connects to a drive unit that pulls the chain.

Belt Conveyor Ovens

This type of conveyor oven contains a woven chain belt that moves parts and materials through the oven. This belt moves in a continuous or indexed manner and can also dwell depending on the production volume and timing.

The oven is ideal for processing huge volumes of small parts and is a safe and reliable solution to the part heat treatment. The parts are put on the wire mesh belt and slide on a steel slider bed.

Applications and Uses of Conveyor Ovens

Conveyor ovens can be used in the curing process, which raises a product's mass and coated material to the appropriate temperature before holding it and letting the product cool down. In drying, the conveyor oven works by removing moisture or other liquids from a product. The conveyor oven is also used in aging, where it is involved in elevating the temperature of a product to change its contained properties.

Choosing the Proper Conveyor Oven Supplier

To ensure you have the most positive outcome when purchasing a conveyor oven from a conveyor oven supplier, it is important to compare several companies using our directory of conveyor oven suppliers. Each conveyor oven supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each conveyor oven business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple conveyor oven companies with the same form.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches