A baking oven refers to pieces of equipment that combine drying and curing ovens under industrial use to result in a dry heating environment. Baking ovens release volatile compounds, moisture, and trapped gasses from coatings on finished products. In the application of powder coating, baking does the job of heating the powder to its melting point to adhere it to a metal piece. Read More…

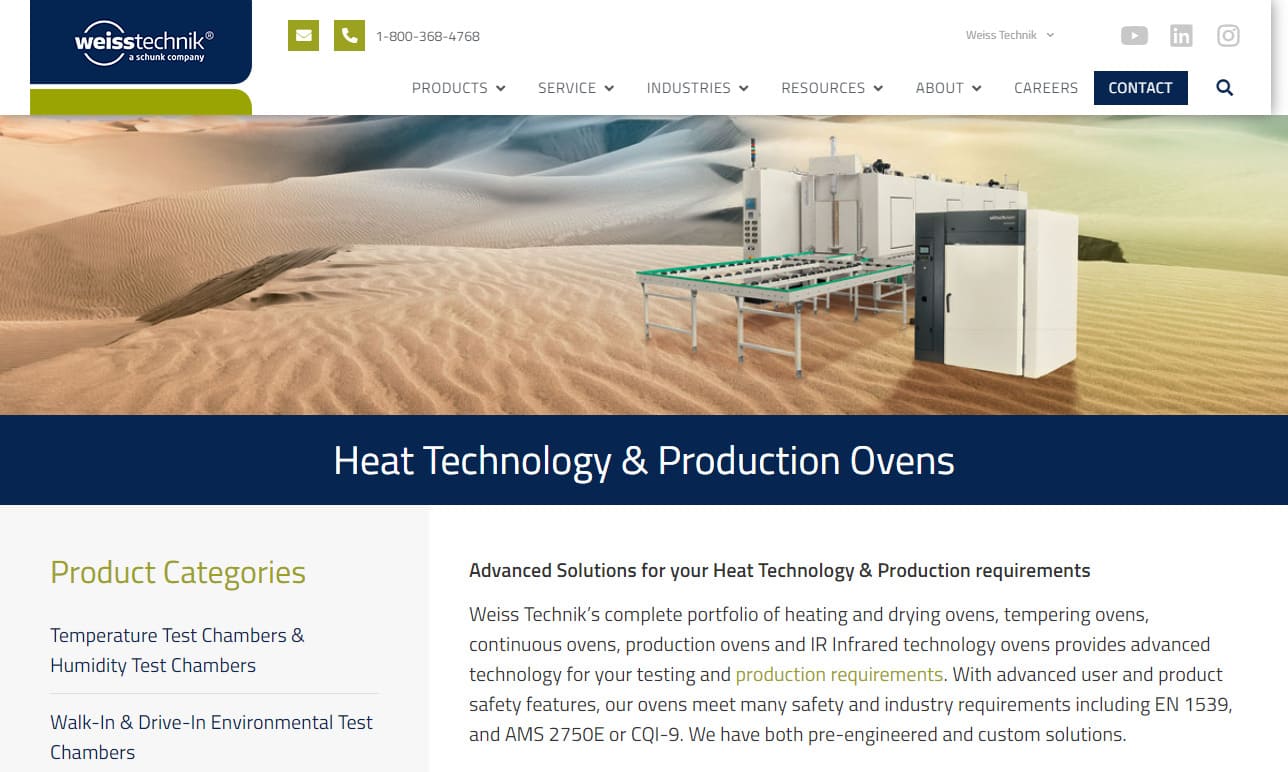

Weiss Envirotronics is a worldwide leader in the design, manufacturer and service of environmental test chambers. A complete line of standard and custom chambers, from bench top models to full walk-in and drive-in solutions to meet any testing requirement. Not sure what you need? Let one of our applications engineers help. Weiss Envirotronics, Inc is ISO 9001 registered and A2LA accredited.

Complete finishing systems are designed around your specific process needs and are optimized to fit within your space requirements. We specialize in producing paint systems for wet and powder coatings, while also providing comprehensive design, fabrication, installation, start-up, and training services. Our complete finishing systems consist of an overhead conveyor, pretreatment washer, dry-off...

Surface Combustion offers a diverse product offering for batch, continuous furnace designs for atmosphere, non-atmosphere, or vacuum processing of ferrous and/or nonferrous components/materials. The convection design is optimal for temperatures between 350°F – 1400°F and are engineered to perform and built to last.

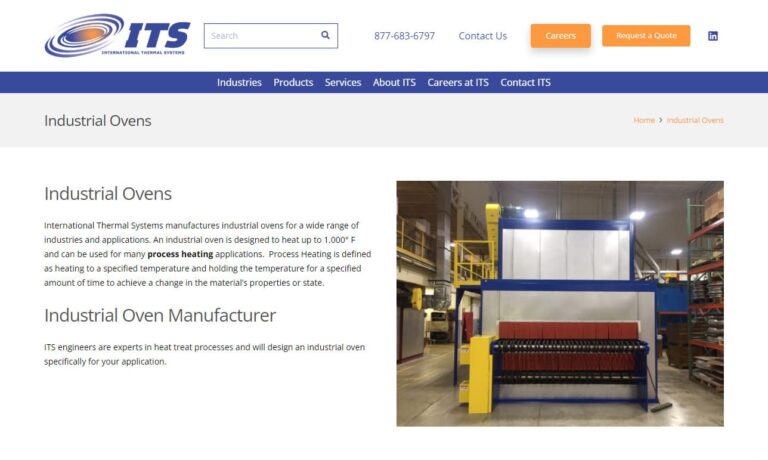

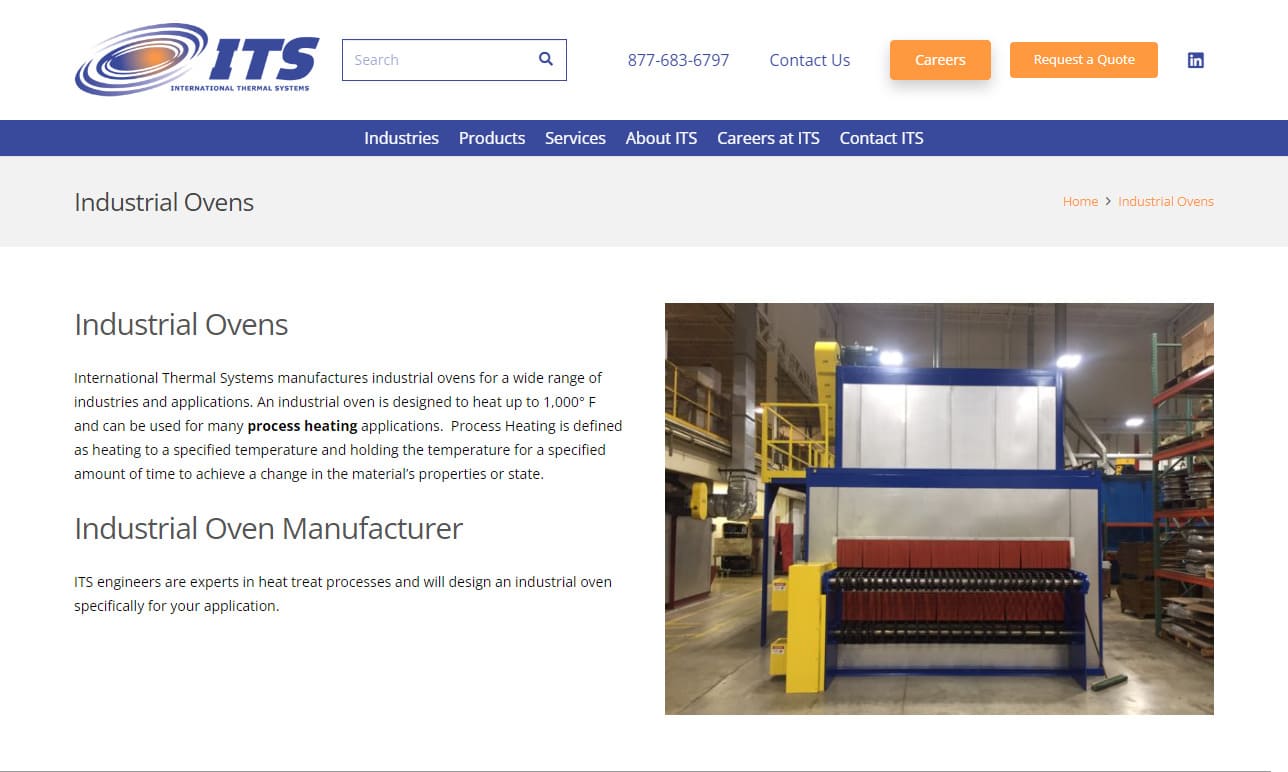

International Thermal Systems manufactures industrial ovens for a wide range of industries and applications. An industrial oven is designed to heat up to 1,000° F and can be used for many process heating applications. Process Heating is defined as heating to a specified temperature and holding the temperature for a specified amount of time to achieve a change in the material’s properties or...

At Ajax Tocco Magnethermic Corp., we are dedicated to pioneering excellence in the field of industrial heating solutions. Our company stands at the forefront of advanced thermal technology, specializing in the design and manufacture of high-performance induction heating systems, industrial ovens, and associated equipment. Our extensive portfolio reflects our commitment to innovation and quality,...

More Baking Oven Manufacturers

What Is a Baking Oven?

Manufacturers use the terms curing and baking interchangeably. These baking ovens are processing thermal units, combining curing and drying. Baking ovens cure painted parts by speeding up the drying process by removing moisture from the air to leave a flawless finish.

The use of batch and conveyor industrial baking ovens is done in the food and packaged food industries to increase the rate of food production.

How Baking Ovens Function

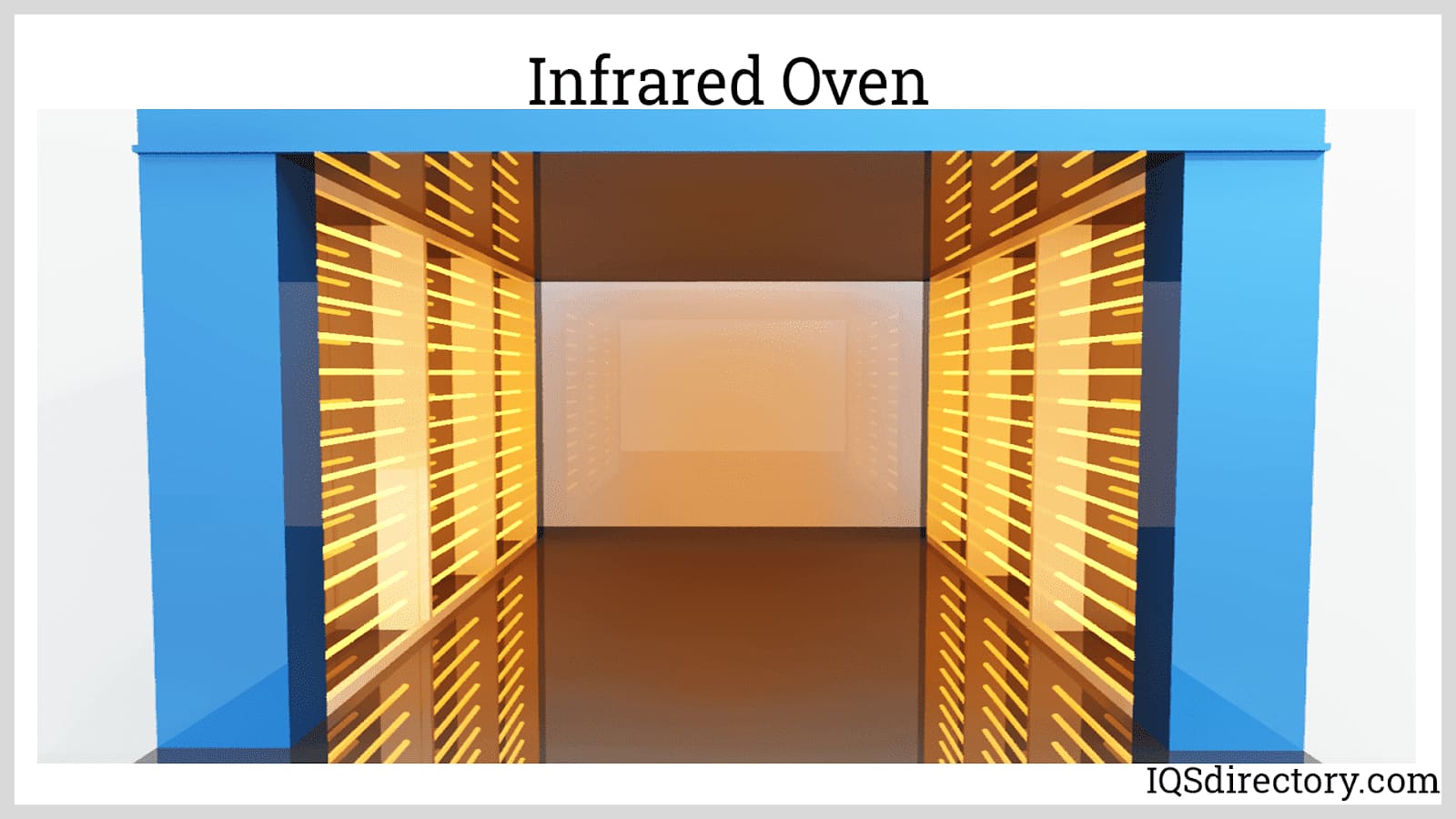

For an effective process in baking the products, ovens put energy generation sources into use, which include electricity and combustion fuels such as oil and gas. The energy released from the power sources is then transferred to the products through radiation, convection, or conduction. The baking oven is set and maintained in line with proper humidity, heat flux, and temperature conditions to maintain the baking process and properly remove moisture from the contained products.

Types of Baking Ovens

Looking at different types of baking ovens generally means looking at the different ways a product can be heated. Heating affects every angle or aspect of a product, from the cooking time to the texture to the appearance.

Direct and Indirect Fired Ovens

These ovens are traditional units for baking. Direct and indirect fired ovens use radiant heat to create a hot baking chamber, which heats food from the inside. They are commonly powered by the use of gas; other sources of power may include oil and electricity. Indirect and direct fired ovens similarly transport heat, but the main difference is in the idea of whether or not the products come in contact as a result of combustion.

Indirect Fired Oven

In this type of oven, the burner does the work of heating the heat exchanger, and this heat exchanger then transfers the heat into the baking chamber. The contained products do not come into contact with the products resulting from combustion. Indirect fired ovens are ideal for products that need lower temperatures and longer baking periods, though their capacities vary based on the application of the product.

Direct Fired Oven

In a direct fired oven, the burner heats the baking chamber directly. In this process, the food product will come in contact with the combustion products. These baking ovens are ideal for products requiring high temperatures and short baking periods. This type of oven has a low cost but also carries a disadvantage--there is a risk of contamination of the product by ash or smoke. The heat retained inside the oven walls is a major part of the baking process.

Impingement Ovens

These ovens are indirect fired baking solutions, meaning that no included combustion products share the baking chamber with the products. These ovens work by surrounding the products with radiant heat, but at the same time, they can use pressurized jets of hot air to penetrate the product. The design of impingement ovens shortens the cooking time by heating the product from the inside and outside.

These baking ovens are ideal for products that need to be processed quickly, but despite this, they are relatively sturdy. In these ovens, a burner heats the heat exchanger, and fresh air is brought in and then heated by the heat exchanger before entering the baking chamber. Then, finally, the air that comes from the burner is let out.

Thermal Oil Ovens

These ovens provide a gentle heat transfer necessary for creating artisan-style products on an industrial scale. Thermal oil ovens contain a high thermal capacity at the same time, also providing precise temperature control.

Applications and Uses of Baking Ovens

These ovens are used for applications that include curing and drying. For example, baking ovens cure painted parts by speeding up the drying process by removing moisture from the air to leave a flawless finish. In addition, they provide pre-baked or pre-cooked food for consumers.

Choosing the Correct Baking Oven Manufacturer

To ensure you have the most productive outcome when purchasing a baking oven from a baking oven manufacturer, it is important to compare several companies using our directory of baking oven manufacturers. Each baking oven manufacturer has a business profile page highlighting their areas of experience and capabilities, and a contact form to directly communicate with the manufacturer for more information or request a quote, Review each baking oven business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple baking oven companies with the same form.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches